Customer Spotlight: Gary’s Steel Storage Building and Workshop

Future Buildings has been a leader in custom steel buildings for over 40 years now, so it’s easy for us to recognize the quality, durability and ease of assembling a steel storage building designed and manufactured by us. We understand that you want to hear from people just like you and learn about their experiences installing a custom steel storage building and workshop!

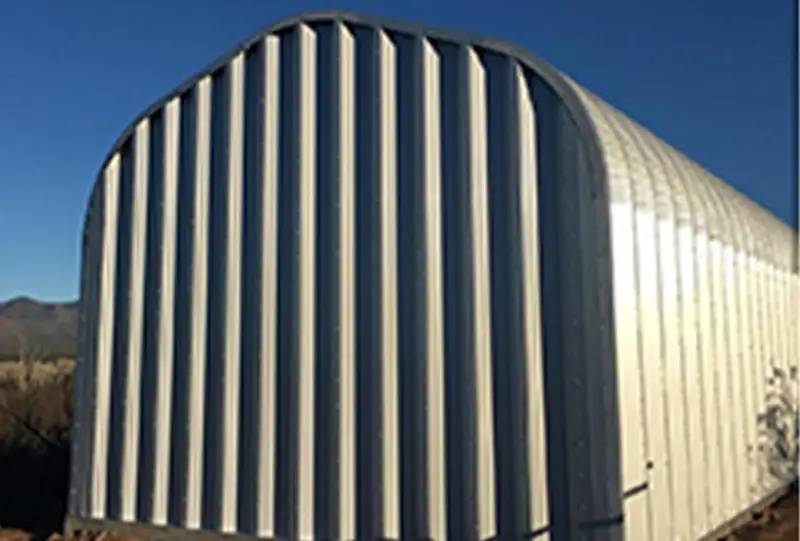

Gary recently erected a steel building on his property in Arizona – we’ll let him tell you about how he found the process, from quote to installation and enjoyment!

Can you tell us about your Future Buildings structure and why you decided to erect a custom steel storage building?

I decided on a custom steel structure based on durability and the ease of erection.

Our building is 20’ wide, 40’ long and 16’ 4” high in the center. The rear wall is solid and we plan to install a steel exterior man door later; the front wall has a framed opening that measures 12’ wide by 10’ high, we will install a roll up door later. An 8’ high 12’ x 20’ loft area for storage will also be installed.

What were your priorities when designing your custom building?

In addition to building for Polaris and boat storage, we’ll be performing several hobbies in our steel building. I will set up woodwork and welding equipment in our steel building and have a separate workshop area for my custom ammunition crafting equipment.

We haven’t spent a lot of time in our new building yet, but all of our hobby equipment will be housed in it with all our toys – so it will see plenty of us before years’ end!

Workshops, carports, storage and more – browse steel building design styles

Why did you decide to work with Future Buildings on your custom steel building project?

I love their frameless design with its clear span interior and that it’s easy for the DIY type.

Future Buildings can customize any dimension building that you want, and they usually have several available for immediate delivery that just may fit your needs.

Learn how you can customize your steel building even more with steel building accessories

Can you share a bit about the process of collaborating with Future Building, from receiving your True Price Quote to delivery?

I submitted a bid on my building via Future Buildings’ website and started our correspondence with Matt Johnson. Matt was very straightforward all the way through the process and Future Buildings even worked with me on the delivery date. We also purchased base plates, which was a very wise choice in retrospect.

What can you tell us about your DIY installation process?

Regarding the installation process, my wife and I were assisted by 3 other people to make a 5-person crew, although one of our crew went home after day 3 (when the building’s shell was up). It took us a week total.

Day 1 was the baseplates; 2 days to erect, center and plumb shell. 1 day to rattle-up all the shell bolts; 2 days for end walls and the framed door opening – and finally 1 day for caulking the base and clean-up inspection.

Was any aspect easier than you anticipated it would be?

Nothing – it looked easy and it was!

We rented a 19’ scissor lift to help make it easier and faster. We centered an arch over the lift, two people supported the corners with notched 2x4s and had a person guiding each arch base and went straight up with the lift. From there you slowly drive the arch in place and install the baseplate bolts, then the arch bolts. We rattled up the baseplates as we went and installed the arch bolts finger tight.

What aspect was more challenging than you anticipated it would be?

Getting these old muscles that I haven’t used like this in a long time to perform every day – I’m 64 and have been retired for 2.5 years!

What would you tell someone who is considering purchasing a Future Buildings steel building, but is nervous about DIY installation?

Get some friends and family lined up and do it – it’s really not that hard to do!

Buy the baseplates, you can actually install them without your crew on Day 1 and they definitely make erecting the building easier and faster.

Rent the scissor lift! Your volunteer crew’s time is valuable to them. Show them that you understand that by renting the scissor lift. It will not only ease erecting the building, but you’ll also be glad to have it when your crew starts to rattle up 3-4 thousand nuts and bolts!

Make sure you have 2-3 cordless impact guns on hand. Also fully read the pertinent sections of the erection manual a few times BEFORE you even start on Step One!

Would you recommend Future Buildings to others? What would you say to someone considering working with Future Buildings?

I would definitely recommend Future Buildings to others – and already have!

Future Buildings is a “no BS” outfit that sells high quality sturdy buildings (that don’t take a contractor to erect) at a reasonable price. They were straightforward with us through the entire process. Some companies kind of forget about you once they have your money, but Future Buildings isn’t like that at all. Their buildings’ uses are as limitless as your own imagination, a Future Buildings steel building is a true multi-purpose building.

Consider this a rock-solid endorsement of Future Buildings!

Get your own custom steel building started today – request a True Pricing Quote from our team now!

Do you have your own Future Buildings structure, or one on the way? You can share images or videos of your finished or in-progress steel building and send them our way!

Submit them to our annual photo and video contest for a chance to win cash prizes and bragging rights!

Contact info@futurebuildings.com for more info.

Related posts